The manufacturing sector naturally takes notice when a new fabrication technology comes along, one that promises an era of homemade products free from specialized machining…

The biography of a high-end tooling company is determined by exceptionally high production standards. Within the workspace of every committed manufacturer is a competitive production environment based on precision engineering practices…

Industry is stacked high with acronyms, but CNC (Computer Numerical Control) lays way down there at the foundations of engineering. Below those foundations, in the basement if we're sticking with unwieldy metaphors, exists the realm of hand tools…

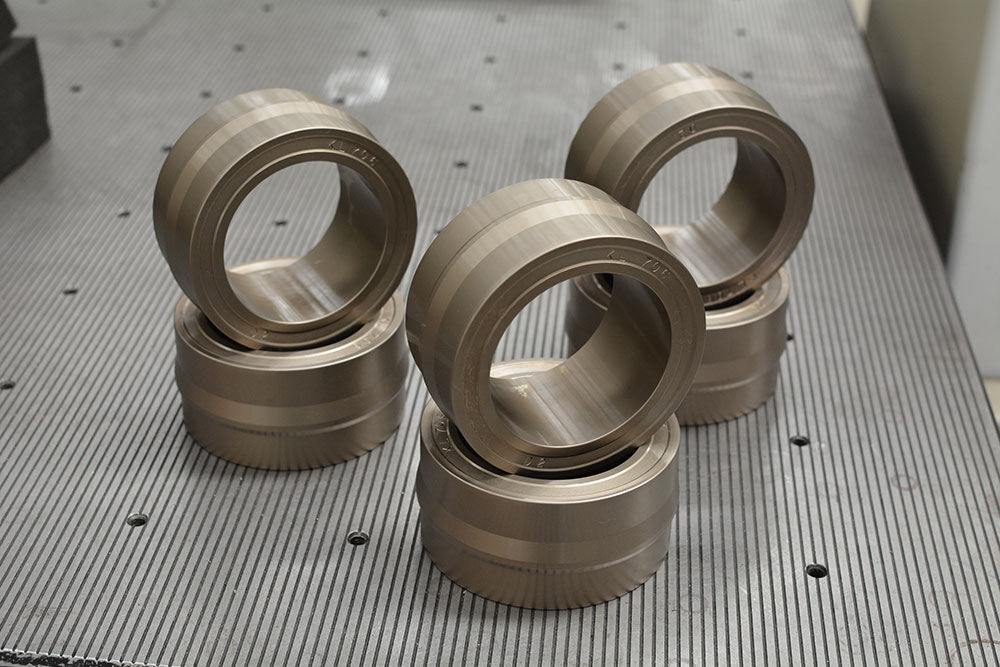

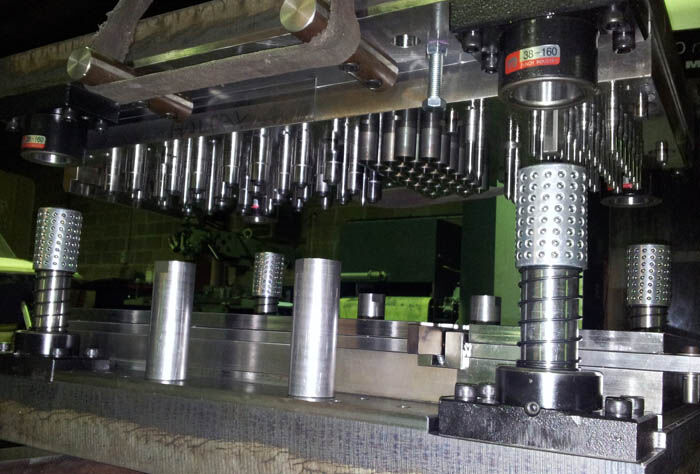

State-of-the-art machined parts can only be persistently produced by employing state-of-the-art tools. It's a simple line of reasoning, one to stick to if a manufacturing company wants to keep an edge in the competitive world of precision engineering…

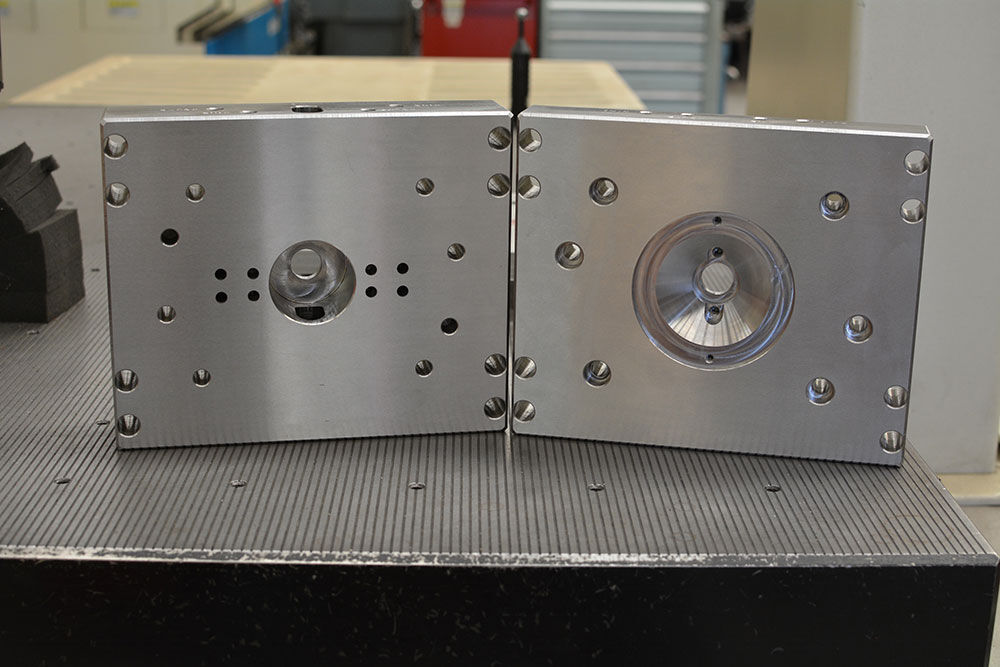

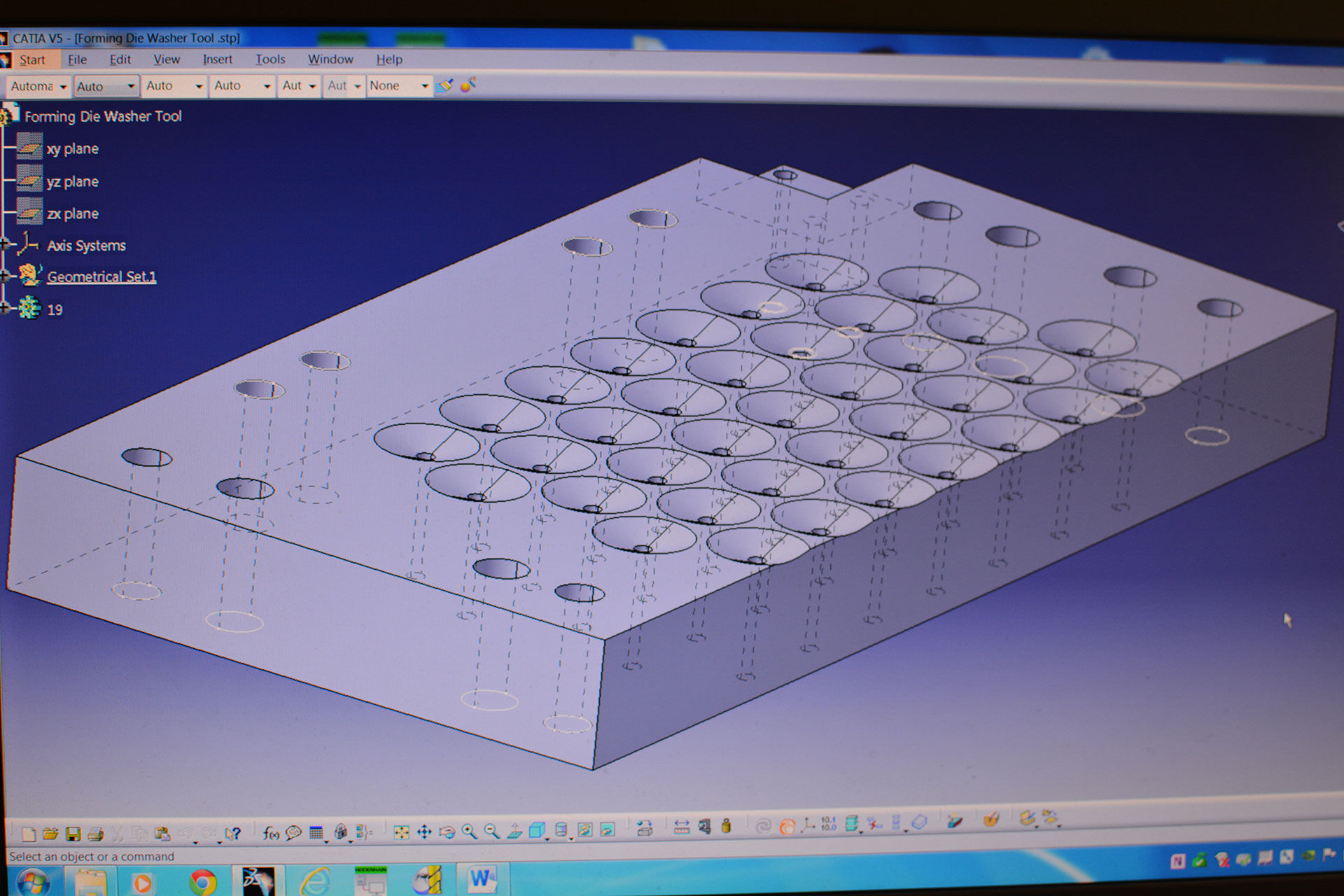

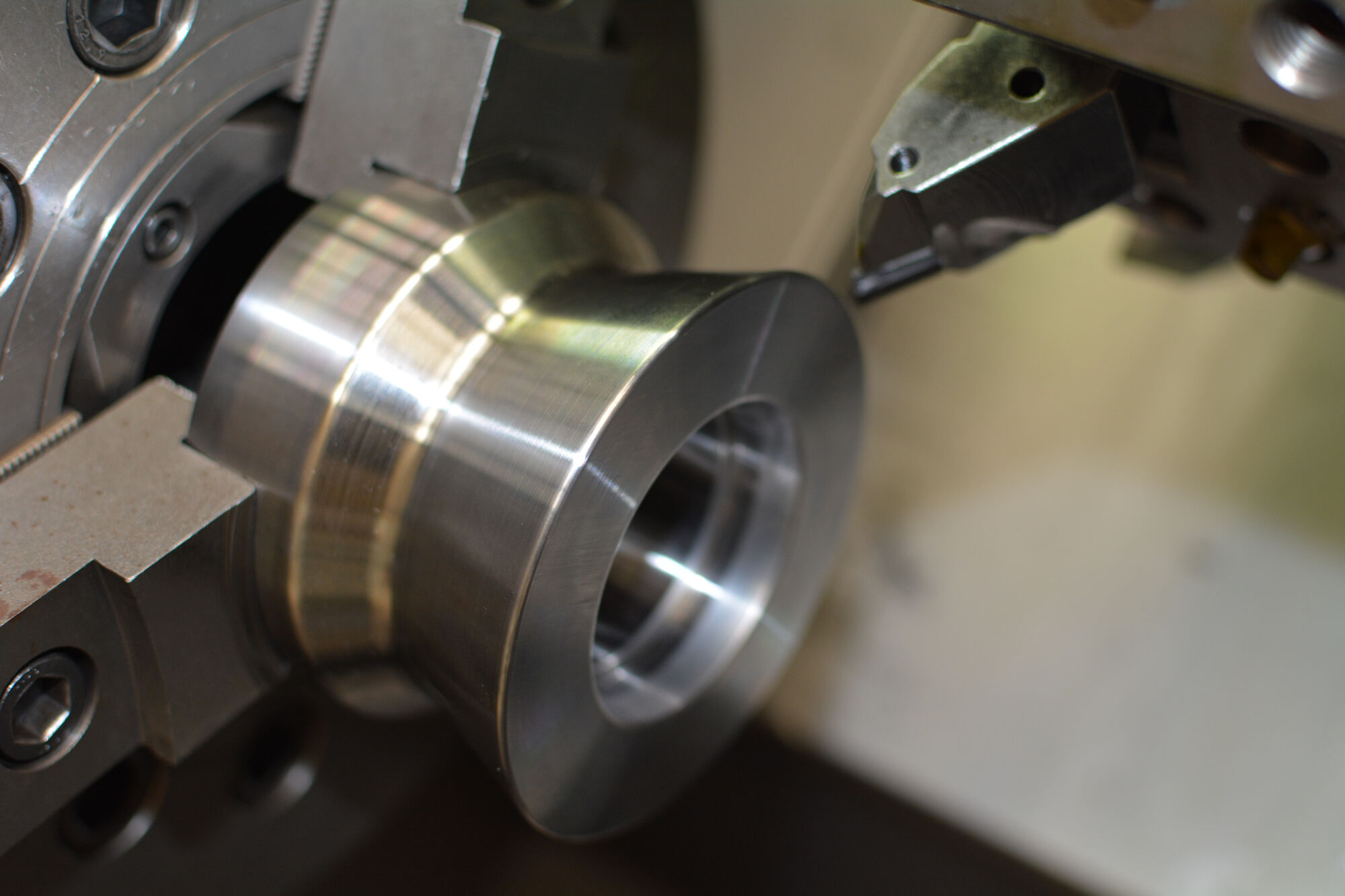

An end-to-end engineering process employs a linear workflow where a design is conceived and then realized. Design data held in computer space or a blueprint acts as the initial stage of prefabrication, with raw materials and capable high-end tooling taking on the role of the developmental stages required to fabricate mechanical parts…

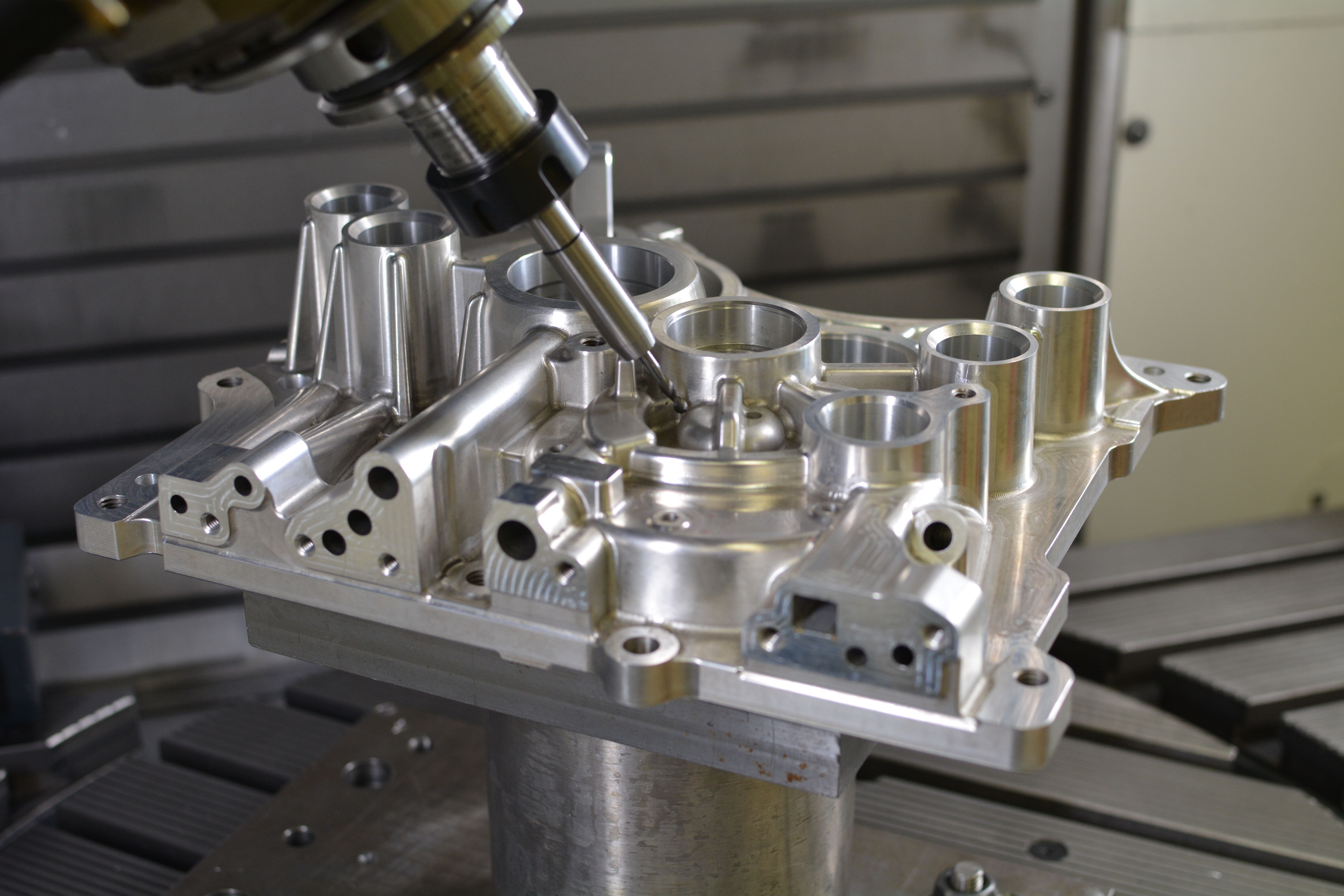

Translating the tight tolerance values inherent to high-end engineering specifications takes a level of machine tooling that exceeds manual labor capabilities…

Following the schemata backwards of a designed product is necessary in figuring out how the product is made to work and what went wrong or what could go wrong in its operation…

Once a tool is sharpened the coating is removed, so it is easy to see why sharpening and coating go hand in hand. This way ensures you get your tools back like new…

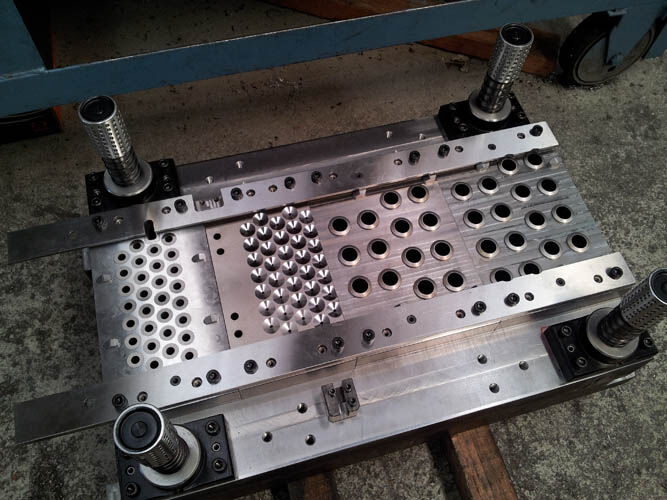

Tooling is a manufacturing process used in several industries including automotive, manufacturing, mining, food, science and general engineering industries…

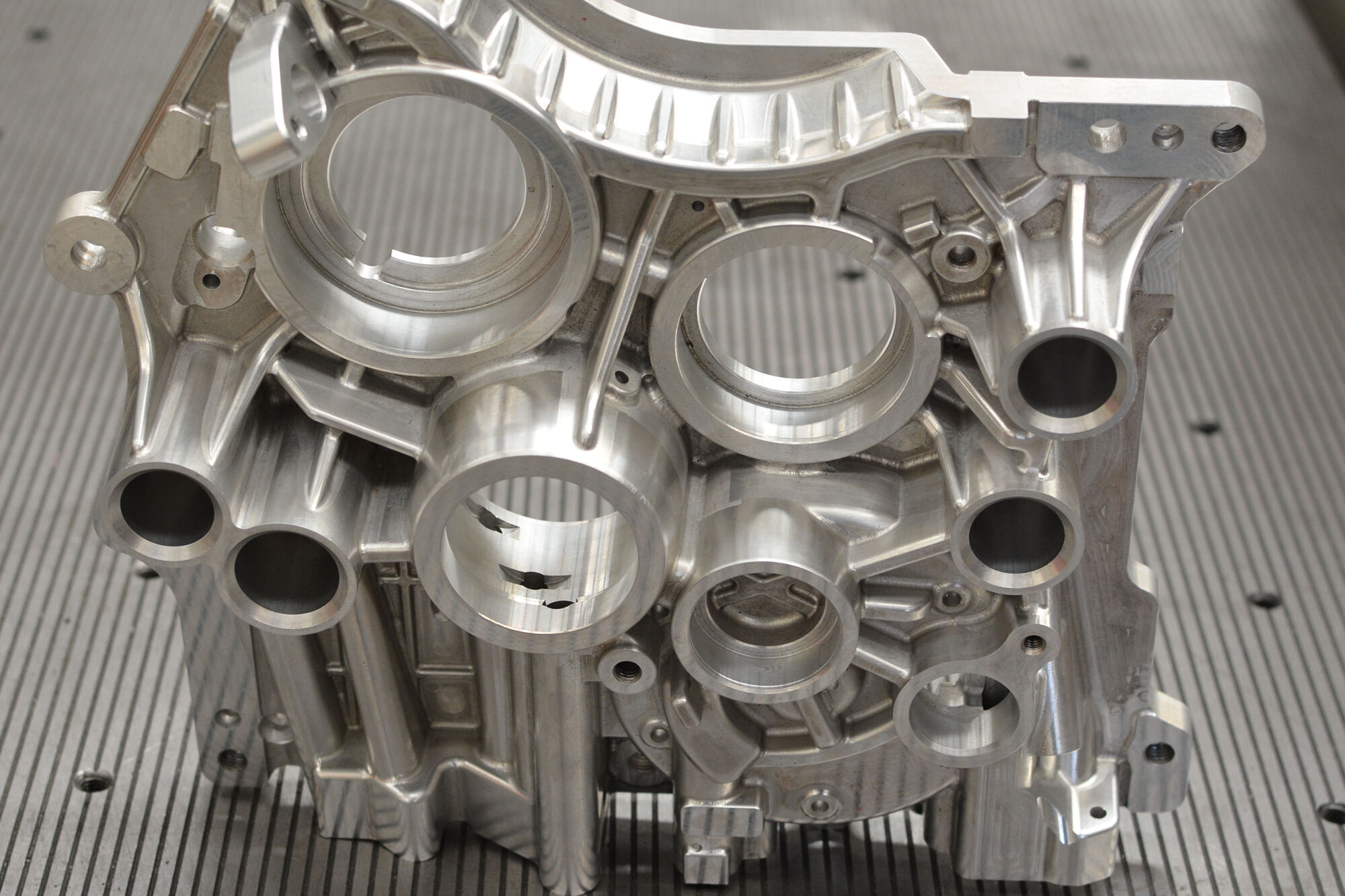

What is 5 axis machining and what is it used for? Today’s machines are more precise than ever before, and companies that can manufacture specialized machine parts have a distinct edge over those companies that cannot…

With the increase in popularity, Computer Aided Design tools, commonly referred to as CAD, are being utilized more frequently than manual drafting…

Prototype development is a way of emerging programs beginning with a prototype and progressively testing and improving it…

Multiaxis machining is a manufacturing process where machine numerically controlled instruments that move in 4 or more ways are utilized to fabricate parts out of metal or different materials by milling away excess material, by water jet cutting or by laser cutting…

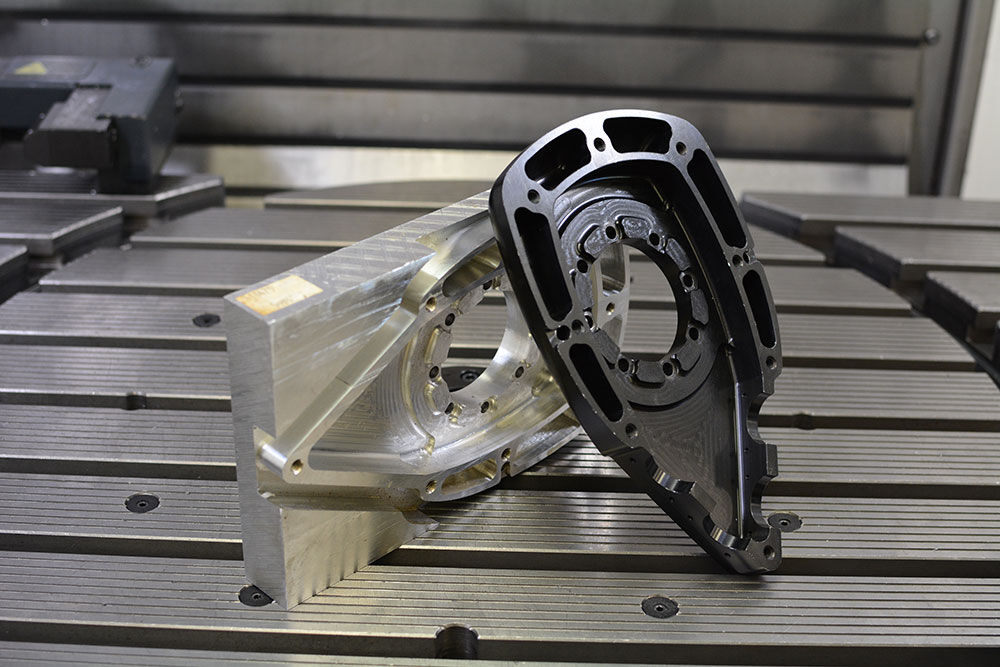

Reverse Engineering is taking apart a specific object and see how it works in order to duplicate its function or enhance the object overall…

Computer Numerical Control (CNC) is a machine that functions according to the series of instructions embedded in coded alphanumeric data created by special software such as Computer Aided Design…