What is a Prototype Development?

Prototype development is a way of emerging programs beginning with a prototype and progressively testing and improving it. The idea first starts as a descriptive statement that is verbalized or written. The idea is then advanced into a product perception that is comprised of the features and client’s benefits.

Next is the development of the prototype; an introductory version or a working model of the product. After a number of recapitulations, the prototype is completed into the final product.

Purpose

Prototype development is referred to as the process of making a system or device that establishes the practicality of a solution to a problem. Generally, prototypes are operated by just the consumer or specific client who comprehends the basic technology. However, there are different kinds of prototypes.

Types

There are various kinds of prototypes that can be complex, simple or functional as follows:

- Dummy prototypes: Utilized for understanding analysis requests

- Demo prototypes: Conveys vision and performance to potential clients

- Proof of principle (POC) prototypes: Used to examine risks and prospects

- Public display prototypes: Generally used by management for budget approval

- Operational prototypes: The most serviceable prototype that oftentimes develops into a finished product

Successful Prototype Development

The process of prototype development should always be meticulous, precise and cater to the needs of the consumer. In order for a prototype development to be successful, there needs to be a few key factors observed and addressed.

- Prompt continual feedback

- Exhibit the prototype to investors often

- Cultivate an operational prototype as fast as possible

- Request continuing endorsement of prototype results

- Keep in mind that the first reiteration will have issues

- Review the prototype method before proceeding to the next prototype cycle

- Preclude alteration of the rudimentary purpose of the prototype development

- Redo the demonstration and revision of the prototype until acceptable functionality is attained

Prompt and Fast Prototyping

Regardless of the intricacy of construction, subtractive or additive techniques are always applied. This is necessary for product excellence. The strengths of the techniques should include:

- Reduction of overall costs in prototype development

- Possible fabrication in diminutive time regardless of geometric complexity

- Simplicity and speed in modifying and correcting design and the subsequent new prototype

Applied Technology

Today, technology is advancing at a rapid rate including prototype development. Research and expansion have supported the advancement of prompt prototyping systems. This reins true especially in regards to performance such as less processing time, enhanced endurance and lower dimensional resistances.

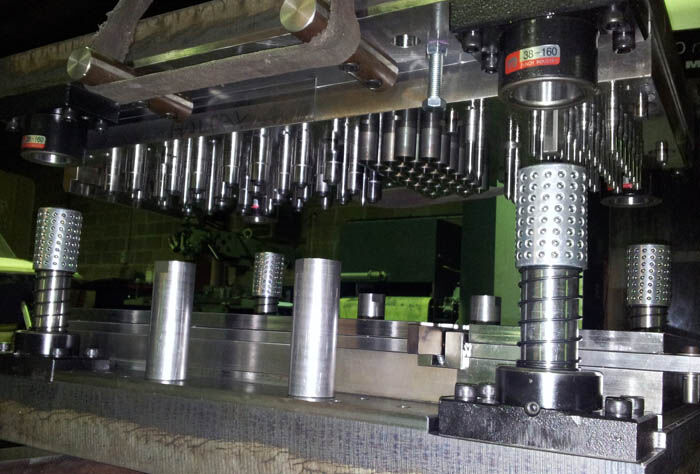

Prototype development can be applied to a wide array of businesses. One of the most leading fields that have expanded in prototype development is the rotary cutting tool industry. Rotary cutting tools require strict guidelines and oftentimes specialized prototypes for both standard and high performance. Prototype development has allowed technology advancement, productivity and efficiency.