What is 5 axis machining

What is 5 axis machining and what is it used for? Today’s machines are more precise than ever before, and companies that can manufacture specialized machine parts have a distinct edge over those companies that cannot. To understand what is 5 axis machining, it will help to first understand what are 2 axis machining, 3 axis machining and 4 axis machining.

What is 5 Axis Machining

Basic machining, where an object is placed on a plane upright to be modified, is based around a two coordinate system. The two coordinates, the x and the y axis, located on the plane give this system the name 2 axis machining. Objects positioned upright on the plane can be modified with great precision top to bottom, forward and back, or left to right. The 2 axis machining system works well; however, with today’s high precision equipment and machine parts, 2 axis machining is limited.

While 2 axis machining is limited, 3 axis machining is able to modify objects from 3 axis points or angles. Using 3 axis machines, just about any basic object can be manufactured. If, that is true, then why need 4 axis machines, or 5 axis machines? That is a logical question and the answer is easy to understand.

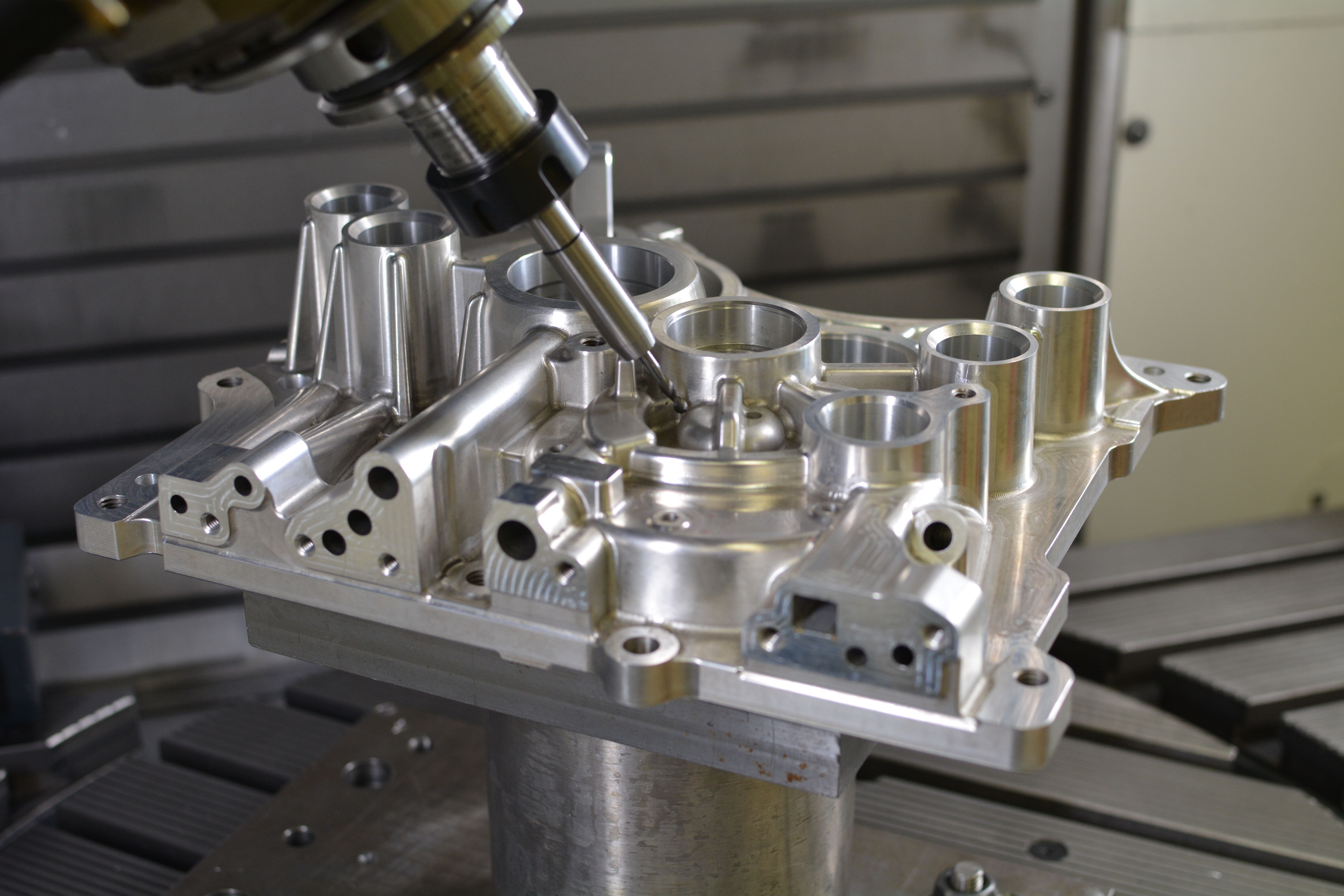

5 Axis Machining Produces Complex Products

Simply put, the more axes on a tooling machine, the more complex pieces and parts that can be produced. With enough axes to work with even a perfect sphere is possible to construct. What is 5 axis machining really good at producing? Well, compared to a 3 axis machine, 5 axis machining has two extra axes to work with to produce more complex products than is possible with 3 axis machines.

Objects can now be rotated in two more ways other than x,y and z. The extra two axis can even be a circular axis or any angle that is needed to complete the final product. Objects can now be rotated and tilted to any desired position to create magnificent art pieces or the most precision machine parts.

Many industries rely on 2 axis machining and 3 axis machines, along with advanced control technology, to manufacture their parts. However, the promise of increased accuracy and speed of manufacturing has compelled many mould shops and tooling companies to consider investing time in discovering what is 5 axis machining.