What Are the Different Types of CNC Machining Tools?

Computer Numerical Control (CNC) is a machine that functions according to the series of instructions embedded in coded alphanumeric data created by special software such as Computer Aided Design. In layman’s terms, it means these machines are controlled by programming a computer; instead of having someone operates or supervise the machine as it perform its task. Among the different types of CNC machining tools the most common tools include:

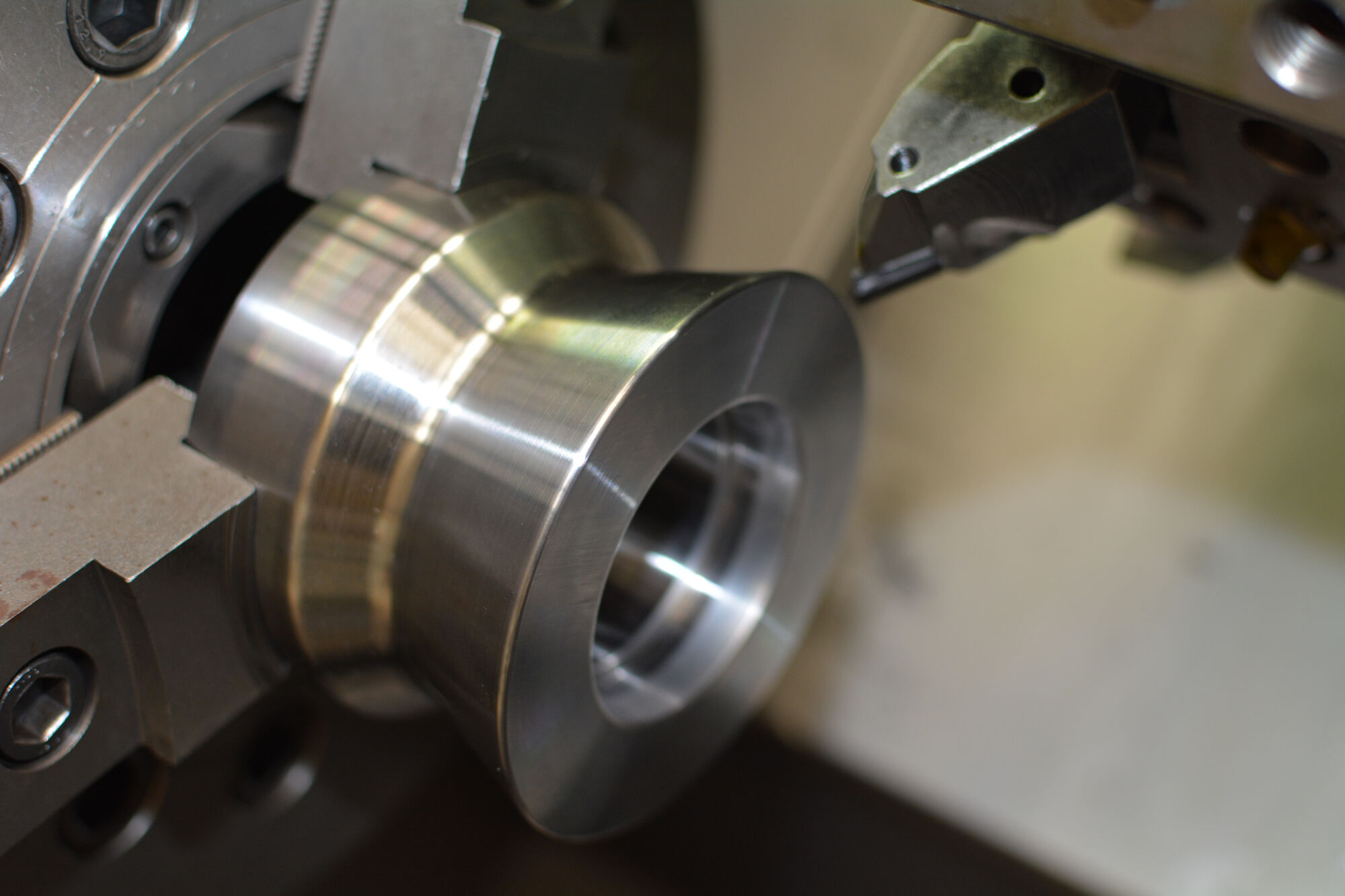

LATHES

Lathes are devices that cut steel that is often switching at quick rates of speed. CNC lathes are able to make quick, precision cuts using indexable resources and drills with complicated programs for parts that normally cannot be cut on manual lathes. These machines often consist of 12 device holders and coolant pumps to cut down on tool wear. CNC lathes have identical control specifications and can analyze and interpret G code as well as the manufacturer's proprietary programming language.

MILLS

This machining device uses computer controls to cut different materials. They are able to convert programs made up of specific number and characters to move the spindle to various places and absolute depths. Many use G code, which is a standardized programming language that all CNC devices understand, while others use exclusive 'languages' created by their manufacturers. These exclusive 'languages' are often simpler than G code, but not transferable to other devices.

GRINDERS

Grinding metal is a process uses a covered rim that gradually eliminates metal to create a part. Through the years, grinding was done on a manual machine, but with the introduction of CNC technology, the procedure has progressed rapidly. Enter the program, which includes the various passes that the wheel will make, and hit start. It is one of the most convenient kinds of CNC devices to work with as they often only contain only one grinding rim.

DRILLS

CNC device follows specific guidelines in the production of a part. A software platform can control the angle of the cut, as well as the depth of the hole being drilled. Computer control is used when the work piece needs repeated drilling or taping cycles. Certain parameters, such as depth, feed rate, retraction and cancellation of the cycle manages the drilling pattern.

Electrical Discharge Machining Machines (EDMs)

Electrical discharge machining is a technique for making tiny, complex cuts or shapes in hardened materials that are different to carve. EDM is only efficient on electrical conductors, and is used mainly on ferrous components. EDM machines fire a sequence of fast electrical jolts from an electrode to burn or vaporize material. The rest of the debris is flushed away with dielectric fluid.